Products

Useful Links

- Choose professional Small Sunflower Seed Oil Refinery Line

- Professionally Designed Mini Oil Mill for Home Use

- Is Small Oil Production Line Worth for Investment?

- How to Build Small Edible Oil Production Line?

- Small Oil Mill Plant for Daily Requirement

- Small Edible Oil Refinery Plant Cost Can Be Reduced Relatively

- How to Extract Palm Oil from Palm Fruit-Oil Mill Plant

- start oil extraction factory

Latest News

Apr 10, 2018

Mar 30, 2018

Edible Oil Refining

Home > Useful Links >

We offer fully tested, premium quality and cost effective Edible Oil Refining Machine with different oil refinery capacity. These Edible Oil Refining require less maintenance and are easy to operate. In addition, use of latest technology helps in offering energy efficient Edible Oil Refining in the market.We are offering our customers a wide range of Edible Oil Refinery Machinery which available in various sizes and specifications as you required.

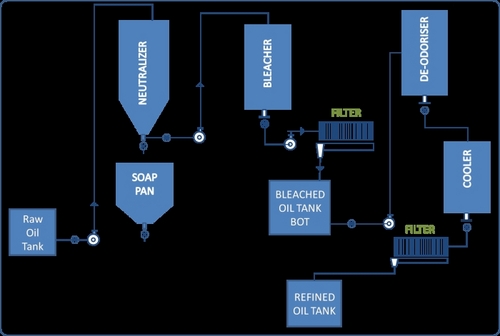

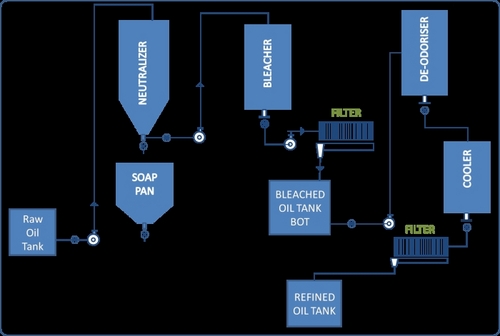

Edible Oil Refining Processing of Solvent Extraction Plant

Degumming Process of Edible Oil Refining

Degummed process of edible oil is heated to 65-70ºC and required quantity of caustic soda solution is added slowly. The reaction is take place between free fatty acid and caustic soda solution and stirring is continues. Soap is formed. Then stirring is stop & soap will setteled down. This soap is remove and 3-4 hot water wash is required to remove soap and alkaly impurities. Oil is totaly neutral. Then we can use in bleaching process.

Neutralization Process of Edible Oil Refining

Neutral oil is heated to 110ºC and required quantity of activated bleaching earth powder and carbon is charged with constant stirring for 1 hour. Then oil is filter to remove spent earth powder. Then we can use in deodourising process.

Bleaching Process of Edible Oil Refining

Most of all edible oils are contains gum. It is necessary to remove from oil. In neutralizer, oil is heated to 60-65ºC & add phosphoric acid 0.06-0.1% with continues stirring for ½ hour & then we can go neutralization process

Doddering Process of of Edible Oil Refining

In deodourising process, smell & fatty matter of oil is remove. Oil is heated 130ºC and open steam is applied and oil is heated upto 180-220ºC with constant open steam during 3-4 hour and oil is cooled and then filter to remove impurity. Oil is ready to use.

Anytime you are interested in our Edible Oil Refining Machine, contact us without hesitation, we are always ready to give you the best service!

Degumming Process of Edible Oil Refining

Degummed process of edible oil is heated to 65-70ºC and required quantity of caustic soda solution is added slowly. The reaction is take place between free fatty acid and caustic soda solution and stirring is continues. Soap is formed. Then stirring is stop & soap will setteled down. This soap is remove and 3-4 hot water wash is required to remove soap and alkaly impurities. Oil is totaly neutral. Then we can use in bleaching process.

Neutralization Process of Edible Oil Refining

Neutral oil is heated to 110ºC and required quantity of activated bleaching earth powder and carbon is charged with constant stirring for 1 hour. Then oil is filter to remove spent earth powder. Then we can use in deodourising process.

Bleaching Process of Edible Oil Refining

Most of all edible oils are contains gum. It is necessary to remove from oil. In neutralizer, oil is heated to 60-65ºC & add phosphoric acid 0.06-0.1% with continues stirring for ½ hour & then we can go neutralization process

Doddering Process of of Edible Oil Refining

In deodourising process, smell & fatty matter of oil is remove. Oil is heated 130ºC and open steam is applied and oil is heated upto 180-220ºC with constant open steam during 3-4 hour and oil is cooled and then filter to remove impurity. Oil is ready to use.

Anytime you are interested in our Edible Oil Refining Machine, contact us without hesitation, we are always ready to give you the best service!

Henan Kingman M&E Complete Plant Co., Ltd ©

Email:info@oilmillplant.com

Français

Français Русский

Русский Español

Español