Products

Useful Links

- Choose professional Small Sunflower Seed Oil Refinery Line

- Professionally Designed Mini Oil Mill for Home Use

- Is Small Oil Production Line Worth for Investment?

- How to Build Small Edible Oil Production Line?

- Small Oil Mill Plant for Daily Requirement

- Small Edible Oil Refinery Plant Cost Can Be Reduced Relatively

- How to Extract Palm Oil from Palm Fruit-Oil Mill Plant

- start oil extraction factory

Latest News

Apr 10, 2018

Mar 30, 2018

Oil Filter Press

Filter press is used for separating solids and liquids in industries such as food, environmental protection, pharmaceuticals, chemicals, metallurgy, oil, etc. It is particularly being used as a oil purifier in the oil processing plants for edible or vegetable oils.

When choosing a filter press, you should know clearly what you going to filter, the daily capacity, material water content, you should also estimate the filtering aera you need, the foundation dimensions of the filter pressing machine in advance. Then you can select the right filer press for you according to technical datas from press filter manufactures, or you can directly ask for adcice from professional manufactures.

Filter press can be generally divided into 3 categories, plate and frame filter press, chamber type filter press and vertical filter press. The first and the third ones are more popular in today's market, and here we will give you simple introduction ablout the two filter press machines.

Filter Presses Used in Oil Mills

The filtrating cloth between the filter plates forms many rooms. The oil under the pressure goes through the filtrating cloth, gets out from the faucet beneath the filtrating cloth. The plate filter press is qualified the technology requirements of the IB/T 4333-1997 the pressure oil-filter in compartmental and plate type.

The materials for board choice are cast iron, ductile iron, reinforced polypropylene, glass fiber polypropylene ( temperature 120℃) and stainless steel. The press methods are handle press, jack press, mechanical press, liquid press, automatic pressure press and advanced automatic microcomputer control. The ways for filter are free flow, undercurrent flow, free flow wash out, undercurrent flow wash out and two-way cross wash. The Polypropylene has the advantages of stable performance, acid and alkali proof, non-toxic, non-smell, non-pollution and easy to handle.

Main Structure

The plate and frame filter press is a basic filtering unit that consisit by filter frame and filter plate. The filter is formed by four parts:Mainframe, filtering parts, press and control. The filter part is constituted by several filter boards and frames which are ranked in the main beam in an order—the filter is between filter board and fram.

Working Principle

When material come into filter room from hole in push plate, the solid bigger than the hole of filter intermediary is hold in the filter room and become solid lump while the liquid flow out from the discharge hole by free flow and undercurrent flow. Under each filter board there is a hole with a water nozzle that the water flow out from the nozzle is called free flow, while the way brings water from each filter boars together and flow out by discharge channel is called undercurrent flow.

Advantages of Vertical Pressure Leaf Filter

Main Structure and Working Principle

The main body of the filter is made up of vessel, filter gauzes, lifting structure and automatic discharging device Filier gauzes are made by material of multilayer stainless steel which installed center liquid pipe and cleaned up conveniently.

In the process of filtration,the unfiltered liquid with filter aid come into the body through transmission system (pump or other tools.After a stable filter cake formed on the filter gauze flakes,the filtrate are filtered through the micropores of filter cake.

When choosing a filter press, you should know clearly what you going to filter, the daily capacity, material water content, you should also estimate the filtering aera you need, the foundation dimensions of the filter pressing machine in advance. Then you can select the right filer press for you according to technical datas from press filter manufactures, or you can directly ask for adcice from professional manufactures.

Filter Press Manufaturer

KMEC supplies a wide range of oil filter presses, which are designed to give maximum filtration efficiency, longer life and least maintenance. Our oil filter press is characterized by convinient operation, stable technical effect, high capacity and low impurity. Available in different sizes and with varied capacities, we can also provide filter press in custom specifications. The filter series of our company accord with the national and related industrial regulations (see in technical parameters) and also be produced according to the customers’special needs. Our products are qualified and have passed the ISO9002 registration.Filter press can be generally divided into 3 categories, plate and frame filter press, chamber type filter press and vertical filter press. The first and the third ones are more popular in today's market, and here we will give you simple introduction ablout the two filter press machines.

Filter Presses Used in Oil Mills

Plate and Frame Filter Press

The plate and frame filter press is formed by filter boards and filter frames or filter boards rows (box-type), under the function of conveying pump, it press the suspension liquid into filter rooms and through filter intermediaries (filter cloth, filter paper and filter membrane) to separate solid and liquid. The filter can be used wildly in petroleum, chemical industry, medicine, sugar, metallurgy, food, china, starch, coal washing, dye, and paint as well as sewage treatment in all industries.6LB Series Plate Filter Press

This plate model filter press is suitable for filter crude oil and refined oil, and it is also could be applied to filter bleaching oil in the oil refining plants.The filtrating cloth between the filter plates forms many rooms. The oil under the pressure goes through the filtrating cloth, gets out from the faucet beneath the filtrating cloth. The plate filter press is qualified the technology requirements of the IB/T 4333-1997 the pressure oil-filter in compartmental and plate type.

|

|

|

6LB-350 Oil Filter Press

|

|

Specifications of the Oil Filter Press

|

Model

|

No.of filter plates

|

Dimension of filter plate

|

Working pressure

|

Productivity

|

Power

|

Dimension

|

Weight

|

|

YLY-250

|

13pcs

|

250*250mm

|

0.3-0.4MPa

|

100kg/h

|

0.75kw

|

780*530*670mm

|

155kg

|

|

YLY-350

|

25pcs

|

350*350mm

|

0.3-0.4MPa

|

200kg/h

|

1.1kw

|

1300*750*700mm

|

470kg

|

BAM Series Plate and Frame Filter Press

The filter series of our company accord with the national and related industrial regulations and also be produced according to the customers’ special needs. Our products are qualified and have passed the ISO9002 registration.The materials for board choice are cast iron, ductile iron, reinforced polypropylene, glass fiber polypropylene ( temperature 120℃) and stainless steel. The press methods are handle press, jack press, mechanical press, liquid press, automatic pressure press and advanced automatic microcomputer control. The ways for filter are free flow, undercurrent flow, free flow wash out, undercurrent flow wash out and two-way cross wash. The Polypropylene has the advantages of stable performance, acid and alkali proof, non-toxic, non-smell, non-pollution and easy to handle.

| Model | Filtering Area(㎡) | Capacity of the filtering chamber(L) | Overall dimension(mm) | Overall weight(mm) | Foundation dimension(mm) |

| BAMS1/320-30U | 1 | 15 | 1210*660*650 | 350 | 710*150*500 |

| BAMS2/320-30U | 2 | 31 | 1565*660*650 | 400 | 1020*150*500 |

| BAMS3/320-30U | 3 | 46 | 1875*660*650 | 455 | 1330*150*500 |

| BAMS4/450-30U | 4 | 61 | 1940*870*870 | 720 | 1160*180*600 |

| BAMS6/450-30U | 6 | 91 | 2250*870*870 | 800 | 1470*180*600 |

| BAMS8/450-30U | 8 | 122 | 2560*870*870 | 880 | 1780*180*600 |

| BAMS12/450-30U | 12 | 182 | 3160*870*870 | 1020 | 2380*180*600 |

| BAMS16/450-30U | 16 | 243 | 3770*870*870 | 1180 | 2990*180*600 |

| BAMJ20/630-30U | 20 | 298 | 3400*1150*1160 | 1980 | 2490*400*800 |

| BAMJ30/630-30U | 30 | 453 | 4220*1150*1160 | 2350 | 3310*400*800 |

| BAMJ40/630-30U | 40 | 595 | 4950*1150*1160 | 2680 | 4040*400*800 |

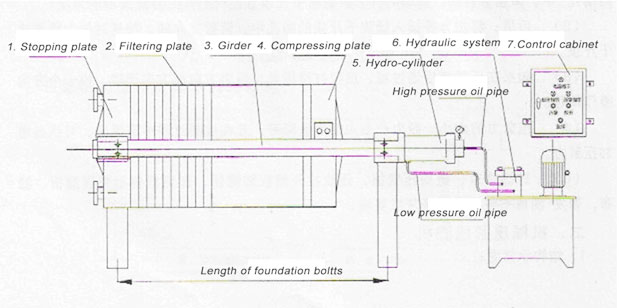

Main Structure

The plate and frame filter press is a basic filtering unit that consisit by filter frame and filter plate. The filter is formed by four parts:Mainframe, filtering parts, press and control. The filter part is constituted by several filter boards and frames which are ranked in the main beam in an order—the filter is between filter board and fram.

Working Principle

When material come into filter room from hole in push plate, the solid bigger than the hole of filter intermediary is hold in the filter room and become solid lump while the liquid flow out from the discharge hole by free flow and undercurrent flow. Under each filter board there is a hole with a water nozzle that the water flow out from the nozzle is called free flow, while the way brings water from each filter boars together and flow out by discharge channel is called undercurrent flow.

Vertical Pressure Leaf Filter

NYB high efficiency vertical pressure leaf filter is a high efficient, energy-saving and hermeticalIy operated fine filter equipment, which is widely used in chemical, petroleum, panting, foodstuff, pharmaceutical and many other industries.

| Model | Filtering Area (㎡) | Filters the cake volume (L) | Capacity for Oil (T/h) | Crosses the filtering jar volume (L) | Main engine weight (Kg) |

| NYB-2 | 2 | 30 | 0.4-0.6 | 120 | 300 |

| NYB-4 | 4 | 60 | 05.-1.2 | 250 | 400 |

| NYB-7 | 7 | 105 | 1-1.8 | 420 | 600 |

| NYB-10 | 10 | 150 | 1.6-3 | 800 | 900 |

| NYB-12 | 12 | 240 | 2-4 | 1000 | 1100 |

| NYB-15 | 15 | 300 | 3-5 | 1300 | 1300 |

| NYB-20 | 20 | 400 | 4-6 | 1680 | 1700 |

Advantages of Vertical Pressure Leaf Filter

- No need of filter cloth and filter paper, greatly reduce the filtering cost;

- All closed operation, environmental protection, no material losses;

- Vibration slag off, greatly reduce labour intensity and realize comtinuous working;

- Pneumatic valve discharge, greatly reduce workers labor intensity;

- Filtering or dehydration with slag or activated carbon (clay) in the liquid instead of plate and frame filter press.

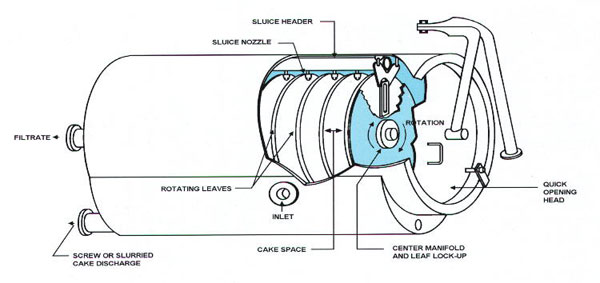

Main Structure and Working Principle

The main body of the filter is made up of vessel, filter gauzes, lifting structure and automatic discharging device Filier gauzes are made by material of multilayer stainless steel which installed center liquid pipe and cleaned up conveniently.

In the process of filtration,the unfiltered liquid with filter aid come into the body through transmission system (pump or other tools.After a stable filter cake formed on the filter gauze flakes,the filtrate are filtered through the micropores of filter cake.

Henan Kingman M&E Complete Plant Co., Ltd ©

Email:info@oilmillplant.com

Français

Français Русский

Русский Español

Español