Products

Useful Links

- Choose professional Small Sunflower Seed Oil Refinery Line

- Professionally Designed Mini Oil Mill for Home Use

- Is Small Oil Production Line Worth for Investment?

- How to Build Small Edible Oil Production Line?

- Small Oil Mill Plant for Daily Requirement

- Small Edible Oil Refinery Plant Cost Can Be Reduced Relatively

- How to Extract Palm Oil from Palm Fruit-Oil Mill Plant

- start oil extraction factory

Latest News

Apr 10, 2018

Mar 30, 2018

coconut oil refining process

Home > Useful Links >

What is Refined Coconut Oil?

Refined coconut oil also known as the RBD Coconut Oil, which refers to the oil that has been refined, bleached, and deodorized. The oil is derived from dried coconut meat known as copra. Actually, the oil that is expelled directly from copra is not fit for consumption, since it may contain dust particles, insect remains, spawns, microbes, fungal spores and many other such substances that may be harmful for health.Refined Coconut Oil is the most easily available, most sold, and most consumed form of coconut oil. In fact, nearly all the coconut oil that comes packed in bottles, sachets and bigger packs in the market is refined coconut oil.

Why Coconut Oil Refining is Necessary?

In almost cases, the kernels are cut open and spread open in the strong sun to dry, with their flesh facing the sun. They are kept like that for days, weeks, or even months until they dry up as desired. They are not even covered with nets. In the absence of sufficiently strong sunshine or in cloudy weather, there are plenty of chances for fungal growth in the kernels, which are neither thrown away nor cleaned before the oil is extracted. Basically, for our own safety, we are left with no choice but to clean the oil instead.Coconut Oil Refining Process

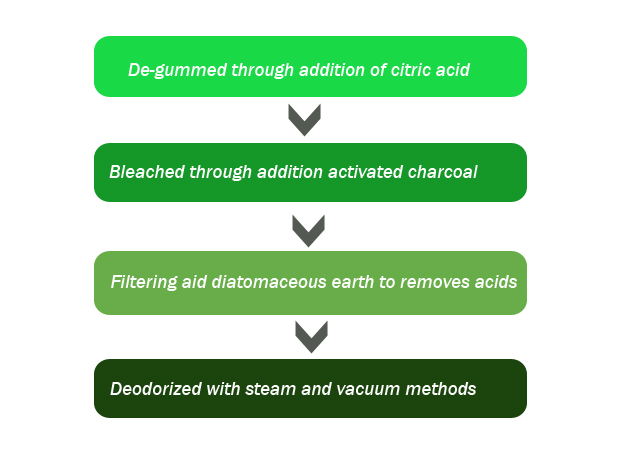

- Product is de-gummed through addition of citric acid.

- Product is bleached through addition activated charcoal.

- The filtering aid diatomaceous earth is added prior to filtering step, which removes the processing aids added in the previous steps.

- Product is deodorized with steam and vacuum methods.

Henan Kingman M&E Complete Plant Co., Ltd ©

Email:info@oilmillplant.com

Français

Français Русский

Русский Español

Español